insulation blender made in china

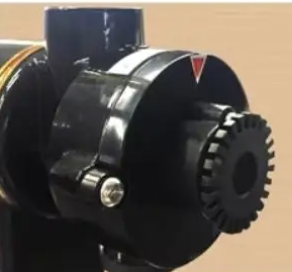

The insulation blender made in China represents a breakthrough in industrial mixing technology, combining superior performance with cost-effectiveness. This advanced equipment features a robust stainless steel construction with double-layer insulation walls, ensuring optimal temperature control during the blending process. The machine operates with a powerful motor system capable of speeds ranging from 500 to 3000 RPM, allowing for precise control over mixing operations. It comes equipped with variable frequency drive technology for smooth speed adjustments and energy efficiency. The blender's insulation system maintains consistent temperatures throughout the mixing process, making it ideal for temperature-sensitive materials. The unit includes multiple safety features such as emergency stop buttons, overload protection, and automatic shutdown mechanisms. With capacities ranging from 100 to 1000 liters, these blenders cater to various industrial needs. The system's intelligent control panel offers user-friendly operation with digital displays for temperature, speed, and timing parameters. These machines find extensive applications in pharmaceutical, chemical, food processing, and cosmetic industries, where temperature control during mixing is crucial for product quality.