insulation blender

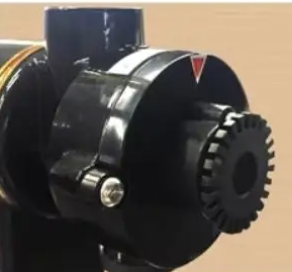

The insulation blender represents a groundbreaking advancement in industrial mixing technology, specifically designed for processing and blending insulation materials. This sophisticated machine combines precision engineering with versatile functionality to deliver consistent, high-quality results in insulation material production. At its core, the insulation blender features a robust mixing chamber equipped with specialized blades that ensure thorough and uniform blending of various insulation components. The machine's advanced control system allows operators to adjust mixing speeds, durations, and sequences with exceptional accuracy, ensuring optimal material consistency. Notable technological features include temperature monitoring systems, automated material feeding mechanisms, and dust control systems that maintain workplace safety and product quality. The machine excels in processing various insulation materials, including fiberglass, mineral wool, cellulose, and synthetic composites. Its applications span across residential construction, commercial building projects, and industrial installations. The insulation blender's sophisticated design incorporates energy-efficient motors and precision-engineered components that minimize maintenance requirements while maximizing operational efficiency. This versatile equipment proves invaluable in modern insulation manufacturing facilities, where consistent product quality and production efficiency are paramount.