baratza encore esp factory

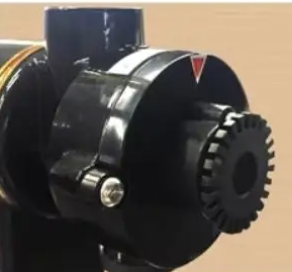

The Baratza Encore ESP Factory represents a significant advancement in home coffee grinding technology, specifically designed for espresso enthusiasts. This state-of-the-art manufacturing facility produces grinders that combine precision engineering with user-friendly features. The factory implements cutting-edge quality control measures to ensure each grinder meets strict specifications for burr alignment, motor performance, and grind consistency. The facility's production line incorporates automated testing stations that verify the 40 grind settings on each unit, ensuring optimal performance across the full range of espresso preparations. The factory's innovative assembly process includes specialized calibration of the conical burr sets, which are made from high-grade steel and designed for longevity. Advanced electronic systems are integrated to maintain consistent speed control and prevent overheating during operation. The facility also features a dedicated research and development department that continuously works on improving grind quality and user experience. Environmental considerations are built into the manufacturing process, with energy-efficient equipment and waste reduction protocols in place. Quality assurance teams conduct rigorous testing at multiple stages of production, including extended run-time tests and grind particle analysis.